GMP Certification for Healthcare Product Companies: Your Guide to Getting It Right

You’re running a healthcare product company—maybe crafting cutting-edge medical devices, whipping up dietary supplements, or producing life-saving pharmaceuticals. Your team’s pouring their heart into every batch, every design, every detail. But then you hit a wall: GMP certification. Those three letters can feel like a locked door to markets like the EU, U.S., or beyond. What’s GMP all about? Why does it matter so much? And how do you navigate the process without losing your cool? Let’s roll up our sleeves and unpack GMP certification for healthcare product companies, blending the nitty-gritty with a dose of real-world relatability.

What’s GMP, and Why’s It a Big Deal?

GMP stands for Good Manufacturing Practices. It’s not just a fancy acronym; it’s a set of guidelines ensuring your healthcare products are safe, consistent, and high-quality. Whether you’re making bandages, vitamins, or injectable drugs, GMP is your promise to regulators and customers that your products won’t harm anyone. Think of it as the recipe for trust in your operation.

For healthcare product companies, GMP compliance is non-negotiable. Mess up, and you’re looking at rejected batches, recalls, or even a shuttered facility. Ever wonder what it feels like to see your product pulled from shelves? It’s a gut punch you don’t want.

The Heart of GMP: Quality Over Everything

GMP isn’t about cutting corners—it’s about doing things right, every time. It covers everything from how you clean your equipment to how you train your staff. The goal? Ensure your products are:

- Safe: Free of contamination, defects, or harmful substances.

- Consistent: Every batch meets the same specs, no surprises.

- Traceable: You can track every ingredient, process, and person involved.

Here’s the thing: GMP isn’t just about passing an audit. It’s about building a culture where quality is second nature. Your customers—hospitals, pharmacies, or patients—depend on it. And regulators? They’re watching like hawks.

Who Needs GMP Certification?

If you’re in healthcare products, GMP applies to you. That includes:

- Pharmaceutical Companies: Making drugs, from pills to injectables.

- Medical Device Manufacturers: Producing anything from syringes to pacemakers.

- Dietary Supplement Makers: Crafting vitamins, protein powders, or herbal blends.

- Contract Manufacturers: If you’re making products for other brands, you’re on the hook too.

Even if you’re a small startup, GMP isn’t optional. Markets like the EU and U.S. require it, and buyers—like hospital procurement teams—won’t touch your products without it. It’s like a driver’s license for your business: no license, no road.

The GMP Certification Process: Your Step-by-Step Game Plan

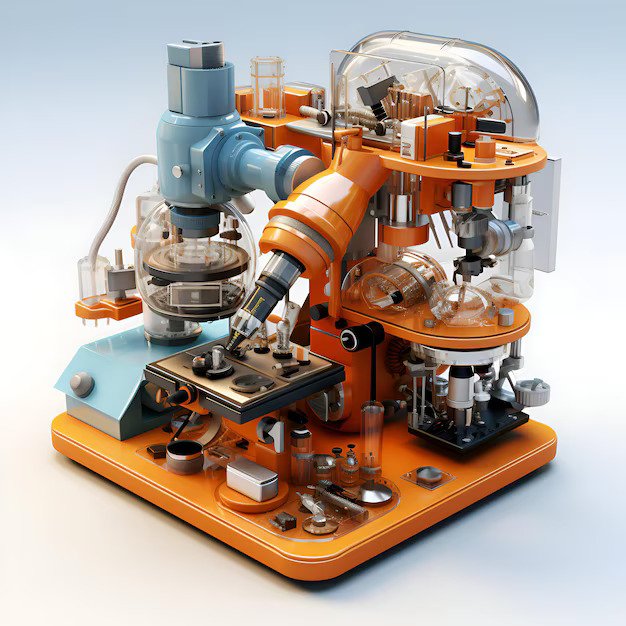

Getting GMP certification isn’t a quick checkbox. It’s a journey, like setting up a sterile cleanroom—methodical, precise, and a little daunting. Here’s how it works.

Step 1: Understand Your GMP Requirements

Different products, different rules. Pharmaceuticals follow stricter GMP guidelines than supplements, while medical devices have their own flavor under ISO 13485 or FDA’s Quality System Regulation. Pro tip: the World Health Organization (WHO) GMP guidelines are a great baseline for global markets.

Step 2: Build a Quality Management System (QMS)

Your QMS is the backbone of GMP compliance. It’s a set of processes, policies, and records that ensure every step of your operation—from raw material sourcing to final packaging—is controlled. Key elements include:

- Standard Operating Procedures (SOPs): Clear instructions for everything—cleaning, testing, labeling.

- Training Programs: Ensuring your team knows the SOPs inside out.

- Quality Control: Testing raw materials, in-process samples, and finished products.

- Documentation: Keeping detailed records of every process, batch, and test.

Tools like MasterControl or Qualio can help manage your QMS, but you can start with simple spreadsheets if you’re small. It’s like organizing a lab—everything needs its place.

Step 3: Train Your Team

GMP is only as good as the people following it. Everyone—from production line workers to quality assurance managers—needs training on GMP principles, your SOPs, and their specific roles. Cover topics like:

- Hygiene practices (no eating in the cleanroom, folks).

- Equipment maintenance and calibration.

- Handling deviations or non-conformities.

- Record-keeping for traceability.

Providers like NSF International, GMP Training Systems, or even online platforms like Coursera offer tailored courses. Make training ongoing—new hires, regulation updates, and refreshers keep everyone sharp.

Step 4: Conduct Internal Audits

Before the regulators show up, audit yourself. Walk through your facility, review your processes, and check your records. Are your SOPs being followed? Is your cleanroom actually clean? Internal audits catch gaps before they become costly problems. If you’re not sure where to start, consultants from firms like SGS or Bureau Veritas can guide you.

Step 5: Get Audited by a Notified Body or Regulator

For certification, you’ll need an external audit. In the EU, a Notified Body like TÜV SÜD or BSI assesses your compliance. In the U.S., the FDA might inspect your facility. They’ll check your QMS, tour your plant, and dig into your records. Pass the audit, and you’ll get your GMP certificate (or a nod from the FDA). Fail, and you’ll need to fix issues and try again. It’s like a health inspection for your favorite restaurant—everything’s got to be spotless.

Step 6: Maintain Compliance

Certification isn’t the finish line. You’ll need to keep your QMS tight, train new staff, and stay ready for surprise audits. Regulators can show up unannounced, and markets like the EU require ongoing compliance checks. Keep your records—batch records, test results, training logs—for years (typically 5–10, depending on the regulation).

The Emotional Weight of GMP

Let’s be honest—chasing GMP certification can feel like running a marathon in a cleanroom suit. It’s exhausting, meticulous, and sometimes frustrating. Why does it feel like regulators are testing your patience as much as your processes? I heard about a small supplement maker who nearly gave up after a failed audit pointed out sloppy documentation. But when they finally got certified, it was like a weight lifted—they could pitch to big retailers with confidence. That’s the deal with GMP: it’s a grind, but it’s your key to credibility.

Challenges You Might Face

GMP certification isn’t all smooth sailing. Here are some hurdles and how to clear them:

- Documentation Overload: GMP requires mountains of paperwork. Use digital tools to stay organized, and double-check for completeness.

- Staff Buy-In: If your team doesn’t take GMP seriously, you’re sunk. Make training engaging—use real-world examples, like a recall case study.

- Regulatory Differences: Exporting to multiple markets? Each has its own GMP flavor. Harmonize your QMS to cover all bases.

- Surprise Audits: Regulators don’t always call ahead. Keep your facility audit-ready at all times.

What’s New in 2025?

Here in July 2025, the healthcare industry’s buzzing with change. The EU’s MDR is in full swing, with stricter rules for medical devices, especially those with software or AI components. If you’re making smart implants or diagnostic tools, expect extra scrutiny on software validation. In the U.S., the FDA’s pushing digital health, so GMP for software-driven devices is a hot topic. Plus, sustainability’s creeping into GMP—expect questions about eco-friendly packaging or waste management.

Technology’s also shaking things up. Digital QMS platforms like Veeva Systems are streamlining compliance, while virtual reality training lets workers practice GMP in simulated cleanrooms. It’s like sci-fi meets quality control—pretty cool, right?

A Healthcare Analogy: GMP as Your Cleanroom

Think of GMP certification like maintaining a cleanroom. You can’t just mop the floor once and call it good—you need constant vigilance, precise protocols, and a team that knows the drill. GMP is your cleanroom for the entire operation, keeping your products safe and your business thriving.

Why GMP Certification Matters

Is GMP certification worth the hassle? No question. It’s your ticket to markets like the EU, U.S., and beyond. It’s what convinces hospitals, pharmacies, and patients that your products are safe and reliable. Without it, you’re stuck on the sidelines. With it, you’re in the game, building trust and opening doors.

So, what’s your next step? Map out your GMP requirements, build a rock-solid QMS, and get your team trained. The road to certification might be long, but it’s paved with opportunity. Your customers—and your business—deserve nothing less.