Top 7 Signs You’ve Outgrown Your Manual Warehouse Processes

You probably didn’t expect your warehouse to grow this fast.

But here you are—orders stacking up, workers scrambling, and spreadsheets multiplying like rabbits. What once felt manageable now feels messy. If you’ve been thinking, “There has to be a better way,” you’re not imagining things. Manual processes have a shelf life.

Here are seven signs your warehouse has hit that breaking point—and how a warehouse management software system can help you regain control without starting from scratch.

1. Inventory Counts Keep Betraying You

You check the system—it says 14 units. You head to the shelf—there are three. Or none.

Manual tracking means someone, somewhere, is updating data by hand. And when people are busy, accuracy takes a hit. Even the most detail-oriented employees get things wrong under pressure.

Common red flags:

-

Stockouts that catch you off guard

-

Phantom inventory showing up in reports

-

Cycle counts that never quite match reality

Let’s face it: guessing shouldn’t be part of your replenishment strategy. Real-time inventory tracking isn’t a luxury anymore—it’s survival.

2. Picking and Packing Feels Like Controlled Chaos

Orders go out late. Labels get mixed up. Wrong items land in customers’ hands. Sound familiar?

You might be relying on printed pick lists, or worse, verbal instructions. As volumes rise, this system breaks down fast.

What this looks like on the floor:

-

Team members double- and triple-checking orders

-

Confusion about bin locations

-

Packing errors leading to costly returns

Accuracy doesn’t improve with more bodies—it improves with better processes.

3. Everyone’s Always in a Rush… Yet Nothing Feels Fast

Some days, your warehouse hums. Other days, it’s a mess of delays and last-minute scrambles.

You start noticing patterns:

-

No one can find what they need

-

Communication is all over the place

-

Orders sit waiting because one step got missed

You can’t fix what you can’t see. And with manual workflows, you’re always a few steps behind the problem.

4. You Keep Throwing People at the Problem

Need to ship more orders? You hire. Then more orders come in, so you hire again. And again.

But your output doesn’t scale the way your payroll does.

Here’s why that’s a problem:

-

Training takes too long

-

New hires slow things down at first

-

Processes don’t adapt—they just get heavier

Instead of adding headcount, what if your system could actually keep up?

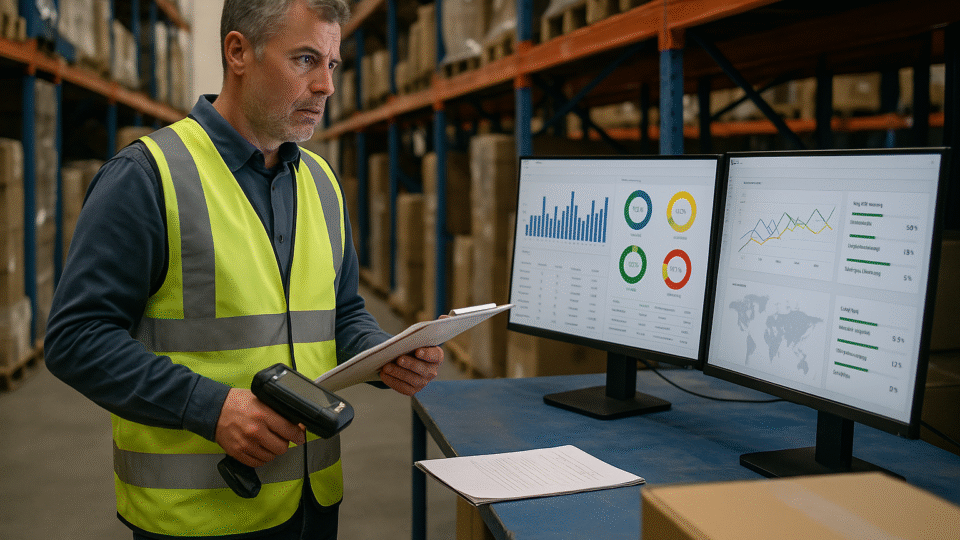

5. Reporting Is a Pain—and Often Too Late to Help

You want to know what’s going on in your warehouse. But the reports you get? They’re static, out of date, or worse—totally wrong.

You ask for a summary, and it takes someone an entire afternoon. And even then, the data might not reflect what’s happening now.

If you’ve ever said:

-

“I just want a snapshot of where we’re at today…”

-

“Why do these numbers feel off?”

-

“We spent how much on returns last month?”

then it’s time to stop relying on retroactive reports and start getting answers in real time.

6. Customers Are Feeling the Gaps—And They’re Letting You Know

They’re not trying to be difficult. But if you keep shipping the wrong product, or shipping it late, or missing the shipment entirely… they’re going to notice.

What shows up in support tickets:

-

“I ordered blue. Why did I get green?”

-

“The tracking number doesn’t work.”

-

“My order said ‘delivered’ but it never came.”

Even loyal customers won’t wait around forever. And the worst part? Most of these issues could be avoided with better coordination.

7. You Sell in Multiple Places… But Your Systems Don’t Talk

Shopify, Amazon, wholesale, direct B2B—your business isn’t one-size-fits-all. So why is your warehouse stuck trying to manage it all with a one-sheet inventory tracker?

What usually happens:

-

Inventory oversells on one channel

-

Orders get missed entirely

-

Staff manually enter data from one system to another

It’s not that your team isn’t working hard—they’re just stuck using tools that can’t keep up.

Time to Switch Gears?

The good news? You’re not alone. Most growing businesses reach a point where manual operations start doing more harm than good. And thankfully, there are smarter tools that fit businesses of all sizes.

A warehouse management software system won’t magically fix every issue overnight. But it can help you:

-

Track inventory in real-time

-

Route orders more efficiently

-

Avoid costly errors

-

Scale without adding more stress

In short—it makes your warehouse work for your growth, not against it.

Final Word: If It Feels Like You’re Duct-Taping Operations Together… You Probably Are

Your team’s doing their best. But when systems aren’t built to scale, even your best people will burn out. If any of these signs sound familiar, that’s your warehouse waving a red flag.

You don’t need to wait for things to break completely before upgrading. Sometimes, the smartest move is to stop, reassess, and give your operations the structure they’ve earned.

You’ve grown. Your warehouse systems should grow with you.

FAQs

1. What’s the biggest risk of sticking with manual warehouse systems?

The biggest risk is losing visibility. Once you can’t track where things are going wrong, you start reacting instead of planning—leading to more delays, mistakes, and lost revenue.

2. How much time can a warehouse management system save per week?

It varies, but many companies report saving 10–30% of time on inventory tasks, order fulfillment, and data entry—sometimes more.

3. Does warehouse software require technical skills to use?

Most platforms are built to be user-friendly. If your team can use a smartphone, they can usually learn the system in a short amount of time.

4. Can I use WMS with the tools I already have?

Yes. Many systems integrate with popular eCommerce platforms, ERPs, and shipping carriers to keep everything connected.

5. How do I choose the right warehouse management software system?

Start by listing your biggest challenges, then look for solutions that address those directly. Ask for demos, test usability, and read case studies from businesses like yours.